Just-In-Time Manufacturing: The Smart Way to Build Better Businesses

Picture this: You walk into a factory and instead of seeing mountains of parts collecting dust, you see a smooth, flowing operation where everything arrives exactly when it’s needed. No waste, no clutter, just pure efficiency. That’s the magic of Just-In-Time manufacturing, and it’s changing how smart companies do business around the world.

How It All Started: A Japanese Success Story

Back in the 1970s, a brilliant engineer named Taiichi Ohno at Toyota had a problem. Japan was short on resources, space was limited, and money was tight. Instead of seeing this as a roadblock, Ohno saw it as an opportunity. He asked a simple question: “What if we only made what we actually needed, when we needed it?”

This wasn’t just wishful thinking. Ohno created a system that would eventually help Toyota become one of the world’s most successful car companies. When American and European manufacturers saw Toyota’s incredible efficiency in the 1980s, they knew they had to learn these secrets or risk being left behind.

The best part? This wasn’t just luck or cultural magic. It was a practical system that any company could learn and use.

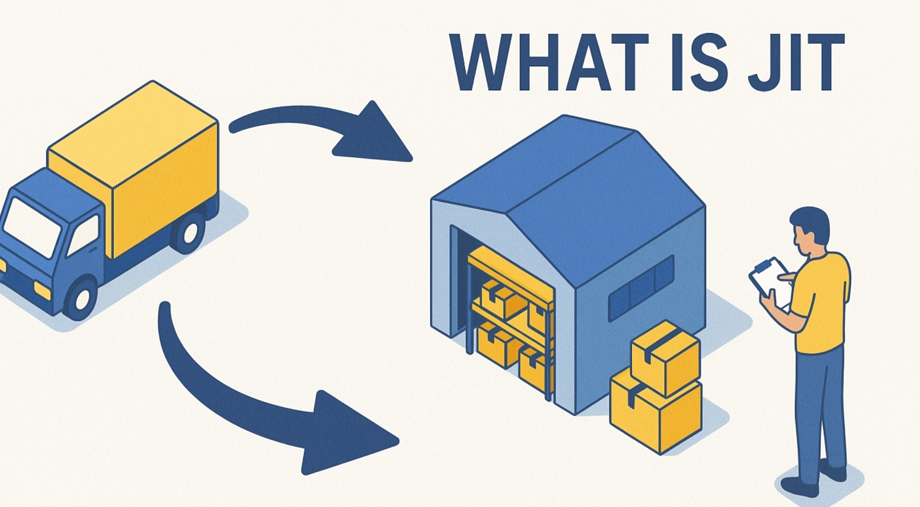

What Is Just-In-Time Manufacturing?

Just-In-Time (JIT) is a powerful tool within lean manufacturing that focuses on producing the right products, in the right quantities, at exactly the right time. As one of lean manufacturing’s most effective tools, JIT eliminates the traditional practice of stockpiling inventory “just in case” and instead creates a system where materials and products flow through production only when they’re actually needed. This lean approach transforms manufacturing from a wasteful, guess-based system into a precise, customer-driven operation that responds to real demand rather than predictions.

The Simple Truth Behind JIT Success

Getting Rid of What Doesn’t Matter

JIT starts with a powerful idea: waste is the enemy. But we’re not just talking about throwing away scraps. JIT identifies seven types of waste that drain money from businesses every day:

- Making too much stuff nobody wants yet

- Workers standing around waiting

- Moving things around unnecessarily

- Doing extra work that adds no value

- Keeping too much inventory sitting around

- People walking back and forth for no good reason

- Making defective products that need fixing

Once you start looking for these wastes, you’ll be amazed at how much money they’re costing your business. The good news? Every single one can be eliminated.

Making Only What People Actually Want

Traditional manufacturing works like this: managers guess what customers might want, then make a bunch of stuff and hope it sells. JIT flips this backwards in the smartest way possible.

Instead of guessing, JIT waits for real customers to place real orders. Then it springs into action, making exactly what’s needed. No more, no less. It’s like having a restaurant that only cooks your meal after you order it, ensuring it’s always fresh and exactly what you want.

Getting Better Every Single Day

Here’s where JIT gets really exciting. It doesn’t just set up a good system and call it done. Instead, it creates a culture where everyone – from the factory floor to the executive suite – is constantly looking for ways to make things better.

This isn’t about massive overhauls that disrupt everything. It’s about small, smart improvements that add up to incredible results over time. A worker might suggest a better way to organize tools. An engineer might find a way to reduce setup time by two minutes. These little victories compound into major competitive advantages.

Building Partnerships That Actually Work

JIT transforms supplier relationships from adversarial negotiations into true partnerships. Instead of constantly switching suppliers for the lowest price, JIT companies invest in long-term relationships with suppliers who share their commitment to quality and reliability.

These partners become extensions of your own company, delivering exactly what you need, when you need it, at the quality level you demand. It’s like having a team of allies working together toward the same goal.

The JIT Toolkit: Simple Systems That Deliver Big Results

The Kanban Magic

Imagine a system so simple that a child could understand it, yet so powerful that it can coordinate complex manufacturing operations across multiple facilities. That’s Kanban – JIT’s visual management system.

Using simple cards or digital signals, Kanban tells everyone in the system exactly what needs to be done and when. No complicated schedules, no confusing reports. Just clear, visual signals that keep everything flowing smoothly. When a downstream process needs more parts, it sends a signal upstream. It’s like having a conversation between different parts of your factory, all speaking the same language.

Quick Changes, Big Gains

One of JIT’s smartest innovations is reducing the time it takes to change from making one product to another. Traditional factories might take hours or even days to switch production lines. JIT companies do it in minutes.

This isn’t just about speed – it’s about freedom. When you can change quickly, you can make smaller batches of different products. This means you can respond faster to customer demands and keep less inventory sitting around taking up space and tying up money.

Quality Built Right In

Most companies inspect quality at the end of the production line. By then, if something’s wrong, you’ve already wasted time and materials making defective products. JIT builds quality into every step of the process.

Workers are trained to spot problems immediately and empowered to stop production if needed. This might sound like it would slow things down, but the opposite happens. By catching problems early, JIT companies actually produce faster and with higher quality than traditional manufacturers.

The Amazing Benefits of Going JIT

Your Money Works Harder

Companies that implement JIT typically see their inventory costs drop by 50% to 90%. That’s not a typo – we’re talking about massive reductions in the money tied up in parts and materials sitting around.

Think about what that means for your business. Less money locked up in inventory means more money available for growth, innovation, and responding to opportunities. It’s like finding a treasure chest in your own warehouse.

Customers Notice the Difference

When your company can respond quickly to orders with high-quality products, customers notice. JIT companies consistently report higher customer satisfaction scores because they deliver what customers want, when they want it, without the quality problems that come from rushing or cutting corners.

Happy customers become loyal customers, and loyal customers drive profitable growth.

Your Team Becomes Unstoppable

JIT transforms workplace culture in amazing ways. When everyone understands how their work contributes to eliminating waste and serving customers better, they become more engaged and motivated. Workers feel empowered to make improvements instead of just following orders.

This creates a positive cycle: engaged employees make better suggestions, which improve the system, which makes work more satisfying, which engages employees even more.

Space Becomes Your Friend

With dramatically less inventory taking up space, you suddenly have room to breathe. Companies use this freed-up space for production expansion, better workflow design, or improved working conditions. Some even rent out excess space for additional revenue.

Smart Ways to Handle JIT Challenges

Building Resilience Into Efficiency

Critics sometimes point to supply chain disruptions as JIT’s weakness. Smart JIT practitioners have learned to build resilience into their systems without sacrificing efficiency.

This means developing multiple suppliers for critical components, maintaining strategic inventory buffers for essential items, and creating flexible systems that can adapt when unexpected problems arise. It’s not about abandoning JIT principles – it’s about applying them intelligently.

Making Change Manageable

JIT implementation doesn’t have to be overwhelming. The smartest companies start small with pilot programs in specific areas or product lines. This lets them learn what works in their unique environment before expanding system-wide.

This gradual approach also helps employees adapt to new ways of working without feeling overwhelmed by too much change at once.

Creating Win-Win Supplier Relationships

Instead of seeing supplier development as a burden, successful JIT companies view it as an investment in their own success. They share forecasts, provide training, establish long-term contracts, and sometimes even help suppliers improve their own operations.

These investments pay dividends through more reliable deliveries, better quality, and often lower total costs as suppliers become more efficient.

JIT in Today’s Digital World

Technology Makes It Even Better

Modern JIT implementations use digital tools to become even more powerful. Internet-connected sensors monitor equipment performance and inventory levels in real-time. Artificial intelligence helps predict demand more accurately. Advanced analytics identify improvement opportunities that humans might miss.

These technologies don’t replace JIT principles – they amplify them, making good systems even better.

Beyond Manufacturing

JIT principles work amazingly well outside traditional manufacturing. Hospitals use JIT to manage medical supplies and reduce patient wait times. Restaurants apply JIT concepts to minimize food waste while ensuring fresh ingredients. Even software companies use JIT approaches to deliver features customers actually want.

The principles are universal: eliminate waste, respond to real demand, improve continuously, and build strong partnerships.

Your Roadmap to JIT Success

Start with Leadership Commitment

JIT success starts at the top. Leaders must commit to the long-term journey and be willing to invest in training, system changes, and cultural transformation. This isn’t a quick fix – it’s a fundamental shift in how you do business.

But leaders who make this commitment consistently report that JIT delivers some of the best returns on investment they’ve ever seen.

Invest in Your People

Your employees are your greatest asset in JIT implementation. Comprehensive training helps everyone understand not just what to do differently, but why these changes matter. When people understand the bigger picture, they become enthusiastic participants rather than reluctant followers.

Recognize and celebrate improvements, no matter how small. This reinforces the culture of continuous improvement that makes JIT successful.

Choose Your Partners Wisely

Success with JIT requires working with suppliers who share your commitment to quality and reliability. This might mean paying slightly more for some components, but the total cost of ownership is typically much lower when you factor in quality, delivery reliability, and reduced inventory costs.

Invest time in developing these relationships. Share your long-term plans, involve suppliers in product development, and work together to solve problems. The strongest JIT companies have suppliers who act like business partners, not just vendors.

The Future is Bright for JIT

JIT manufacturing continues to evolve and improve as new technologies and methods emerge. Artificial intelligence is making demand forecasting more accurate. Blockchain technology is improving supply chain transparency. Sustainability concerns are driving new innovations in waste reduction.

Companies that embrace JIT principles while staying flexible enough to adapt to new challenges and opportunities will continue to thrive. The fundamental insights of JIT – eliminate waste, respond to real demand, improve continuously, and build strong partnerships – remain as relevant today as they were when Taiichi Ohno first developed them at Toyota.

The question isn’t whether JIT works – decades of success stories prove that it does. The question is whether you’re ready to transform your business with these powerful principles. The companies that answer “yes” and take action will find themselves with significant competitive advantages in efficiency, quality, customer satisfaction, and profitability.

JIT isn’t just about manufacturing – it’s about building a better business. And in today’s competitive world, that’s exactly what you need to succeed.

Post Comment