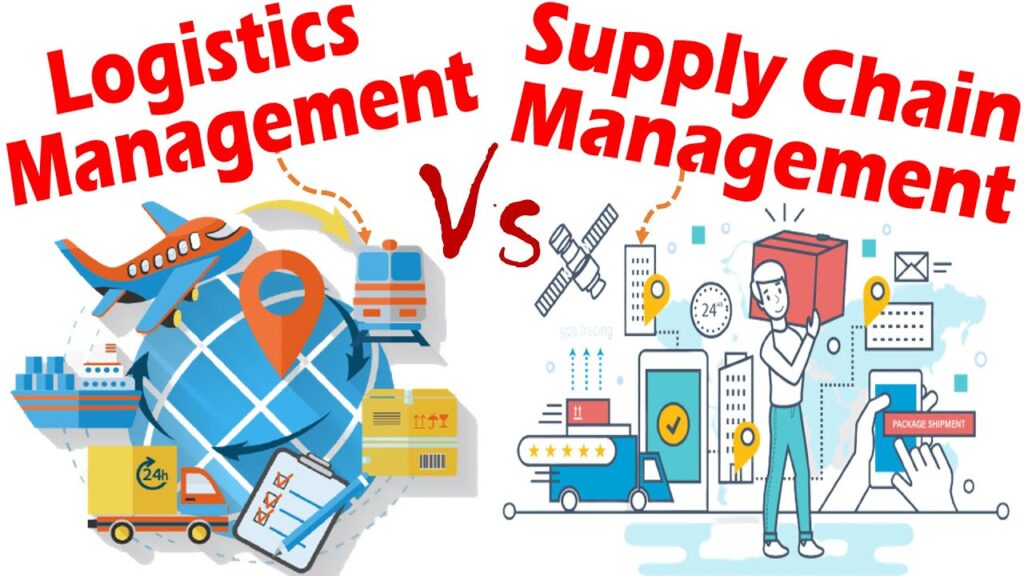

Supply Chain vs Logistics: What You Need to Know in 2025

If you’ve ever wondered about the difference between logistics and supply chain management, you’re not alone. These terms are often used interchangeably in business conversations, but they actually refer to different aspects of how products move from manufacturers to customers. Let me break it down for you in simple terms.

What is Logistics?

Think of logistics as the “how” of moving things around. It’s the tactical, day-to-day operations that focus on getting products from point A to point B efficiently. Logistics is like being the coordinator of a complex dance – making sure everything moves smoothly, on time, and at the right cost.

Key aspects of logistics include:

- Transportation (trucks, ships, planes, trains)

- Warehousing and storage

- Inventory management

- Order fulfillment

- Packaging and handling

- Distribution

Real-world example: Amazon’s logistics operation is legendary. When you order a book online, logistics handles getting that specific book from a warehouse shelf, packaging it properly, choosing the best shipping method (truck, plane, or local delivery), and tracking it until it reaches your doorstep. Every step of that physical movement is logistics in action.

What is Supply Chain Management?

Supply chain management is much broader – it’s the “big picture” strategy that encompasses the entire journey of a product from raw materials to the final customer. If logistics is the coordinator, supply chain management is the orchestra conductor, overseeing all the different players and ensuring they work together harmoniously.

Supply chain management covers:

- Supplier relationships and sourcing

- Product design and development

- Manufacturing and production planning

- Quality control

- Demand forecasting

- Risk management

- Customer service

- Logistics (yes, logistics is part of supply chain!)

- Return and recycling processes

Real-world example: Let’s look at how Apple manages its iPhone supply chain. It starts with sourcing rare earth metals from mines around the world, working with suppliers in multiple countries to manufacture components like screens and processors, coordinating assembly in factories (mainly in China), managing global distribution to retail stores and customers, and even handling the return and recycling of old devices. This entire network of relationships, processes, and decisions is supply chain management.

The Key Differences Explained Simply

Scope and Focus

- Logistics: Narrow focus on moving and storing products efficiently

- Supply Chain: Broad focus on the entire network from raw materials to customer satisfaction

Time Horizon

- Logistics: Short-term, operational decisions (daily, weekly, monthly)

- Supply Chain: Long-term, strategic planning (quarterly, yearly, multi-year)

Responsibilities

- Logistics: Transportation, warehousing, inventory control, order processing

- Supply Chain: Supplier selection, demand planning, risk management, relationship building, overall strategy

A Simple Analogy

Imagine you’re planning a wedding:

- Logistics would be like coordinating the day-of activities: making sure the flowers arrive on time, the catering truck knows where to go, the chairs are set up properly, and guests can find parking.

- Supply Chain Management would be like planning the entire wedding from start to finish: choosing vendors, negotiating contracts, managing your budget, coordinating between the photographer, caterer, florist, and venue, planning for backup options if it rains, and ensuring everything aligns with your vision and budget.

How They Work Together

Here’s the important part: logistics and supply chain management aren’t competitors – they’re teammates. Supply chain management sets the strategy and overall direction, while logistics executes the day-to-day operations that make that strategy work.

Example from the food industry: McDonald’s supply chain management team decides to source potatoes from specific farms, negotiates contracts, and plans for seasonal variations in supply. Meanwhile, McDonald’s logistics team handles getting those potatoes from farms to processing plants, then to individual restaurants, making sure each location has enough fries to meet customer demand without waste.

Why Understanding the Difference Matters

For businesses, knowing the distinction helps in:

- Hiring the right people: A logistics specialist might excel at optimizing delivery routes, while a supply chain manager might be better at negotiating supplier contracts

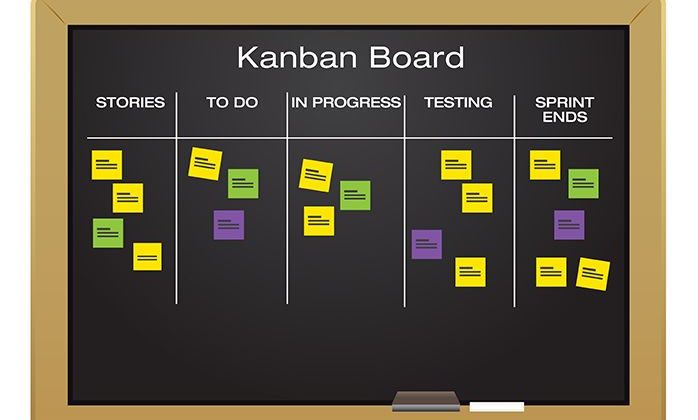

- Investing in the right technology: Logistics might need warehouse management systems, while supply chain needs demand forecasting software

- Solving the right problems: A delivery delay might be a logistics issue, but frequent stockouts might be a supply chain planning problem

The Bottom Line

While logistics and supply chain management are closely related, they serve different purposes in getting products to customers. Logistics is the tactical execution – the nuts and bolts of moving things efficiently. Supply chain management is the strategic orchestration – the big-picture planning that ensures all parts of the system work together effectively.

Both are essential for modern business success. Great logistics without good supply chain strategy is like having a fast car with no map – you’ll move quickly but might not reach the right destination. Great supply chain strategy without solid logistics execution is like having a perfect plan that never gets implemented.

Understanding these differences can help you appreciate the complexity behind every product that reaches your hands, from the morning coffee you drink to the smartphone you’re probably reading this on. It’s a fascinating world of coordination, planning, and execution that keeps our modern economy moving.

1 comment