Global Supply Chain Challenges in 2025: What You Need to Know

Global supply chains are like the nervous system of the world economy. They connect factories, suppliers, and customers across continents, making sure products get from where they’re made to where they’re needed. But in 2025, these vital networks face serious challenges that affect everything from the price of groceries to the availability of smartphones.

What Are Supply Chains?

Before diving into the challenges, let’s understand what we’re talking about. A supply chain is the entire process of making and delivering a product. It starts with raw materials, moves through manufacturing, and ends when the product reaches the customer. For example, a simple t-shirt might involve cotton farmers in India, textile mills in Bangladesh, printing facilities in Vietnam, and retail stores in the United States.

The Major Challenges of 2025

1. Climate Change and Extreme Weather

Climate change is hitting supply chains hard. Floods, hurricanes, droughts, and heat waves are becoming more common and more severe. These weather events can shut down factories, damage transportation routes, and destroy crops.

In 2025, companies are struggling with unpredictable weather patterns. A drought in one region can affect food supplies worldwide. A major storm can close ports for weeks, causing delays that ripple through the entire global economy. Companies now have to plan for weather disasters that were once rare but are now becoming normal.

2. Rising Shipping Costs

The cost of moving goods around the world has gone up dramatically. Fuel prices remain high, and shipping companies are charging more for their services. Container shipping rates, which dropped after the pandemic peaks, are rising again due to increased demand and limited capacity.

This affects everyone. When it costs more to ship products, those costs get passed on to consumers. Everything from electronics to clothing becomes more expensive. Small businesses are hit especially hard because they don’t have the bargaining power that large corporations have with shipping companies.

3. Labor Shortages

Finding enough workers is a major problem across the supply chain. Warehouses, ports, trucking companies, and factories are all struggling to hire people. An aging workforce, changing job preferences, and competition from other industries have created serious staffing gaps.

The trucking industry is particularly affected. There aren’t enough truck drivers to move all the goods that need transportation. Ports are backed up because there aren’t enough workers to load and unload ships quickly. These labor shortages create bottlenecks that slow down the entire system.

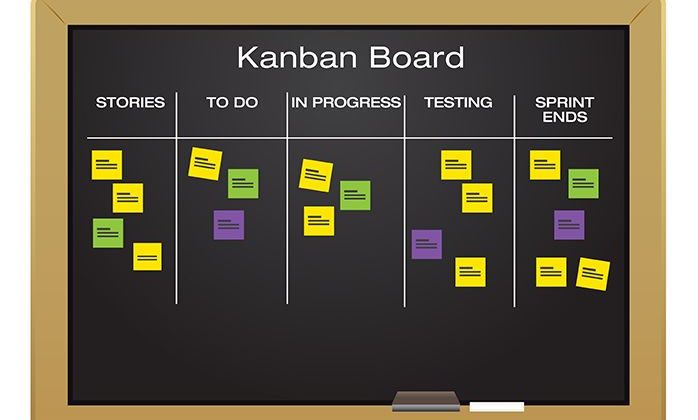

4. Technology Integration Problems

While technology can solve many supply chain problems, implementing new systems is challenging. Many companies use outdated computer systems that don’t talk to each other well. Upgrading to modern technology is expensive and complicated.

Small and medium-sized businesses often can’t afford the latest tracking and management systems. This creates weak links in the supply chain where visibility is lost. When companies can’t see what’s happening with their products in real-time, they can’t respond quickly to problems.

5. Political Tensions and Trade Wars

Politics is making global trade more complicated. Countries are imposing tariffs, trade restrictions, and sanctions that disrupt established supply chains. The ongoing tensions between major economies like the United States and China create uncertainty for businesses.

Companies that relied on suppliers from certain countries are being forced to find new sources. This process, called “reshoring” or “friend-shoring,” is expensive and time-consuming. It also creates temporary shortages while new supply relationships are established.

6. Cybersecurity Threats

As supply chains become more digital, they become targets for cyber attacks. Hackers can shut down production lines, steal sensitive data, or disrupt logistics networks. These attacks are becoming more sophisticated and more common.

A single cyber attack can affect multiple companies in a supply chain. When one supplier gets hacked, it can cause problems for all their customers. Companies now have to invest heavily in cybersecurity, which adds to their costs.

7. Raw Material Shortages

The world is running short of some essential raw materials. Rare earth metals needed for electronics, lithium for batteries, and even basic materials like sand and concrete are becoming harder to find. Competition for these materials is driving up prices and creating supply bottlenecks.

This problem is made worse by the push toward renewable energy and electric vehicles, which require large amounts of specific materials that are already in short supply.

8. Regulatory Compliance

Governments around the world are creating new rules and regulations that affect supply chains. Environmental regulations, labor laws, safety standards, and trade requirements are constantly changing. Companies struggle to keep up with all these rules across different countries.

Failure to comply can result in fines, product recalls, or being banned from certain markets. This forces companies to spend more time and money on compliance instead of focusing on efficiency.

The Ripple Effects

These challenges don’t exist in isolation. They create a domino effect throughout the global economy. When one part of the supply chain has problems, it affects everything else. Consumers see empty shelves, higher prices, and longer wait times for products. Businesses struggle with unpredictable costs and delivery schedules.

Solutions and Adaptations

Despite these challenges, companies are finding ways to adapt:

Diversification: Instead of relying on single suppliers, companies are spreading their risk across multiple sources and regions.

Technology Investment: Businesses are investing in better tracking systems, artificial intelligence, and automation to improve efficiency and reduce dependence on human labor.

Local Sourcing: Some companies are moving production closer to their customers to reduce transportation costs and risks.

Sustainability Focus: Organizations are building more environmentally friendly supply chains that can better withstand climate-related disruptions.

Collaboration: Companies are working more closely with their suppliers and competitors to share information and resources.

Looking Ahead

The supply chain challenges of 2025 require long-term thinking and significant investment. Companies that adapt successfully will have competitive advantages, while those that don’t may struggle to survive.

Consumers will need to adjust their expectations. The days of next-day delivery for everything at rock-bottom prices may be ending. Instead, we might see more focus on durability, local production, and sustainable practices.

Governments also have a role to play. They can invest in infrastructure, create supportive policies, and help coordinate responses to major disruptions.

Conclusion

Global supply chains in 2025 face unprecedented challenges from climate change, rising costs, labor shortages, and geopolitical tensions. These problems affect everyone, from large corporations to individual consumers.

However, these challenges also create opportunities for innovation and improvement. Companies that successfully navigate these difficulties will build more resilient, efficient, and sustainable supply chains. The future of global trade depends on how well we adapt to these new realities.

The key is to remember that supply chains are not just business concerns – they affect the daily lives of billions of people around the world. Solving these challenges requires cooperation, investment, and a willingness to change how we think about global commerce.

Post Comment