Quality Management Systems (SMQ): Complete Implementation Guide 2025

A Quality Management System (SMQ) is a structured framework that helps organizations deliver consistent products and services. Furthermore, it ensures that customer requirements and legal standards are always met. In today’s competitive business world, having an effective SMQ is essential for companies that want to keep customers happy, run efficient operations, and achieve long-term growth.

What is a Quality Management System?

A Quality Management System is a collection of business processes, procedures, and responsibilities that work together to achieve quality goals. Additionally, it provides a systematic approach to managing and improving all aspects of an organization’s operations. This includes everything from product development and manufacturing to customer service and continuous improvement.

Moreover, the SMQ includes the organizational structure, planning activities, responsibilities, practices, procedures, processes, and resources needed to implement quality management. Consequently, it serves as the foundation for ensuring that quality requirements are consistently met while building a culture of continuous improvement.

Key Parts of an SMQ

1. Quality Policy and Goals

The quality policy shows the organization’s commitment to quality and provides a framework for setting quality goals. Furthermore, it should fit the organization’s situation, include a commitment to satisfy requirements, and continually improve the SMQ. Additionally, it provides a foundation for establishing quality objectives.

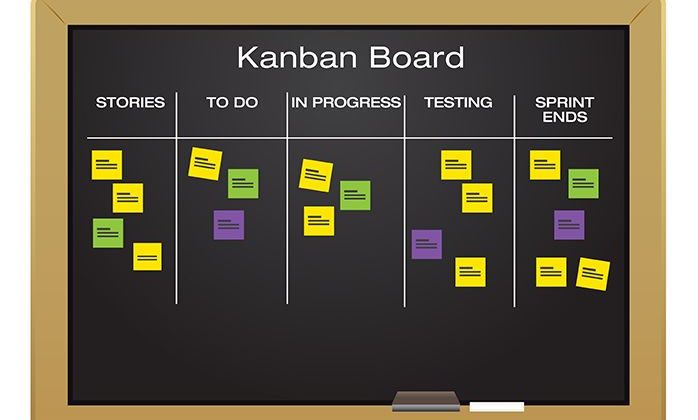

2. Process Management

Effective SMQ implementation requires a process-based approach where organizations identify, understand, and manage related processes as a system. This includes:

- Core processes that directly add value for customers

- Support processes that help core processes work effectively

- Management processes that control the system

3. Document Control

A strong documentation system ensures that all quality-related information is properly controlled, updated, and available to relevant staff. Therefore, this includes quality manuals, procedures, work instructions, and records that show conformity to requirements.

4. Resource Management

Organizations must determine and provide adequate resources for implementing and maintaining the SMQ. Consequently, this includes human resources, infrastructure, work environment, and monitoring and measuring resources.

5. Risk Management

Modern quality management systems emphasize risk-based thinking. As a result, organizations must identify, assess, and address risks and opportunities that could affect the quality of products or services.

ISO 9001: The International Standard

ISO 9001 is the internationally recognized standard for quality management systems. Moreover, it provides a framework for organizations to establish, implement, maintain, and continually improve their SMQ. The standard is based on several quality management principles:

- Customer Focus: Understanding and meeting customer requirements while striving to exceed expectations

- Leadership: Creating unity of purpose and direction for quality initiatives

- People Engagement: Involving competent and empowered people at all levels

- Process Approach: Managing activities as related processes

- Improvement: Continuous improvement as a permanent goal

- Evidence-based Decision Making: Basing decisions on data analysis and evaluation

- Relationship Management: Managing relationships with interested parties

Benefits of Using an SMQ

Operational Benefits

First, implementing an SMQ leads to improved process efficiency and consistency. Additionally, it reduces waste and rework while ensuring better resource use. Furthermore, enhanced productivity and standardized operations across the organization become achievable.

Customer-Related Benefits

Similarly, customer satisfaction and loyalty increase significantly. Moreover, product and service quality improves while response time to customer complaints decreases. As a result, brand reputation and credibility are enhanced, leading to competitive advantage in the marketplace.

Financial Benefits

Furthermore, costs are reduced through improved efficiency. Additionally, liability and insurance costs decrease while profitability improves through better resource management. Consequently, organizations gain enhanced ability to win new business and potential for premium pricing due to quality reputation.

Organizational Benefits

Finally, employee morale and engagement improve significantly. Moreover, internal communication becomes better while management gains enhanced visibility into operations. Therefore, a systematic approach to problem-solving develops, creating a foundation for continuous improvement.

How to Implement an SMQ

Phase 1: Planning and Preparation

First, conduct a gap analysis against applicable standards. Then, define the scope of the SMQ and establish a project team and timeline. Additionally, secure management commitment and resources while developing a quality policy and objectives.

Phase 2: Documentation Development

Next, create or update quality manual and procedures. Furthermore, develop work instructions and forms while establishing document control procedures. Finally, train personnel on new documentation.

Phase 3: Implementation

Subsequently, begin operating according to documented procedures. Moreover, conduct internal training and awareness programs while starting to collect quality records and data. Additionally, monitor process performance continuously.

Phase 4: Internal Audit and Review

Then, conduct internal audits to assess system effectiveness. Furthermore, address non-conformities and improvement opportunities while performing management review of the SMQ. Finally, make necessary adjustments and improvements.

Phase 5: Certification (if desired)

Lastly, select an accredited certification body and undergo external audit process. Additionally, address any findings from the certification audit. Finally, maintain certification through surveillance audits.

Common Challenges and Solutions

Challenge 1: Resistance to Change

Organizations often face employee resistance when implementing new quality systems. However, this can be addressed through effective communication, training, and demonstrating the benefits of the new system.

Challenge 2: Too Much Documentation

Creating excessive documentation can burden operations. Instead, focus on necessary documentation that adds value and supports process effectiveness.

Challenge 3: Lack of Top Management Support

Without leadership commitment, SMQ implementation often fails. Therefore, ensure management understands the benefits and actively participates in the process.

Challenge 4: Limited Resources

Limited resources can slow down implementation. However, developing a phased approach allows for gradual implementation while maintaining operations.

Best Practices for SMQ Success

- Start with Leadership Commitment: First, ensure top management is fully committed and actively involved in the SMQ implementation and maintenance.

- Focus on Processes, Not Just Documentation: While documentation is important, the emphasis should be on effective processes that deliver results.

- Engage Employees: Moreover, involve employees in the development and improvement of the SMQ to gain buy-in and use their expertise.

- Use Data for Decision Making: Additionally, establish metrics and regularly analyze performance data to drive continuous improvement.

- Customer-Focused Approach: Furthermore, keep customer requirements and satisfaction at the center of all quality initiatives.

- Regular Review and Improvement: Finally, continuously monitor, measure, and improve the SMQ through management reviews and internal audits.

Measuring SMQ Effectiveness

Organizations should establish key performance indicators (KPIs) to measure the effectiveness of their SMQ:

- Customer satisfaction scores

- Non-conformity rates

- Process performance metrics

- Corrective and preventive action effectiveness

- Audit findings trends

- Employee feedback and engagement scores

- Cost of quality measurements

Future Trends in Quality Management

The field of quality management continues to change with technological advances and changing business environments:

- Digital Transformation: Integration of digital technologies to enhance quality processes

- Artificial Intelligence and Machine Learning: Predictive quality analytics and automated quality control

- Risk-Based Thinking: Greater emphasis on proactive risk management

- Sustainability Integration: Including environmental and social responsibility into quality systems

- Agile Quality Management: Adapting quality approaches for faster-paced, flexible business models

Conclusion

A well-implemented Quality Management System serves as a powerful tool for organizational success. Furthermore, it provides structure, consistency, and a pathway for continuous improvement. While the initial implementation may require significant effort and resources, the long-term benefits in terms of customer satisfaction, operational efficiency, and business performance make it a worthwhile investment.

Moreover, organizations that successfully implement and maintain an effective SMQ position themselves for sustainable success in an increasingly competitive marketplace. Therefore, the key lies in viewing quality management not as a burden or compliance requirement, but as a strategic tool that drives excellence throughout the organization.

Finally, by following established standards like ISO 9001, focusing on customer needs, engaging employees, and maintaining a commitment to continuous improvement, organizations can build strong quality management systems that deliver lasting value to all stakeholders.

Post Comment