The Power of TPM: Making Machines and Teams Work Better Together

I’ve worked in factories long enough to know – when machines break, everything falls apart. Orders pile up, customers get angry, and you’re stuck working weekends to catch up.That’s where TPM comes in. Total Productive Maintenance sounds fancy, but it’s really just smart thinking. Don’t wait for things to break – fix problems before they happen. The best part? Everyone helps out. Machine operators listen for weird noises. Maintenance guys do regular check-ups. Even the cleaning crew spots oil leaks. When the whole team watches for problems, breakdowns happen way less often.

With competition so tight these days, you can’t afford surprises. One broken machine messes up your entire schedule. But when everyone’s looking out for issues, things run much smoother. That’s TPM in a nutshell getting your whole team to care about keeping things running right.

What Is Total Productive Maintenance?

You can think of Total Productive Maintenance (TPM) as the medical care for machines. It’s a smart way of taking care of equipment and keeping everything running smoothly. TPM is more than just fixing things when they break. It’s a new way of looking at maintenance—one that helps boost production while also making workers feel more involved and satisfied with their jobs.

With TPM, maintenance becomes a key part of the business. It’s no longer seen as something that just costs money without giving anything back. Instead of waiting for something to go wrong, maintenance is planned during normal working hours—and sometimes even built right into the production process.

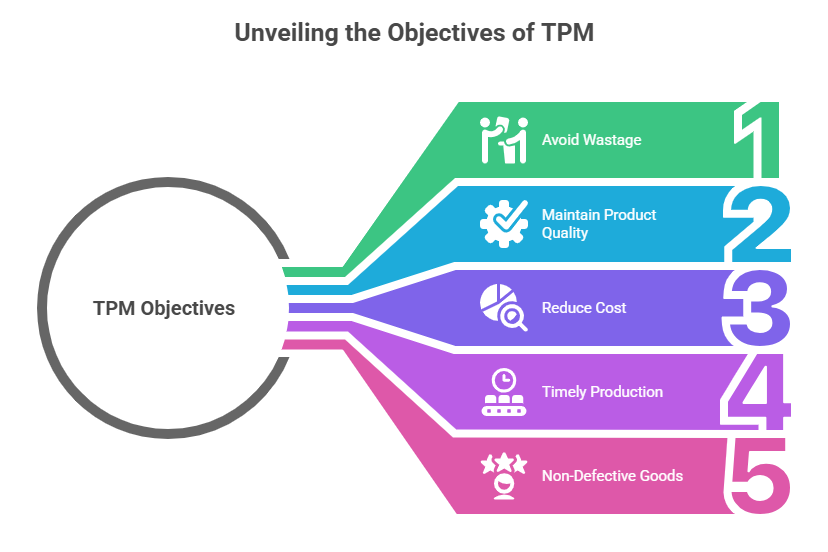

The main goal? To reduce unexpected breakdowns and avoid last-minute repairs as much as possible.

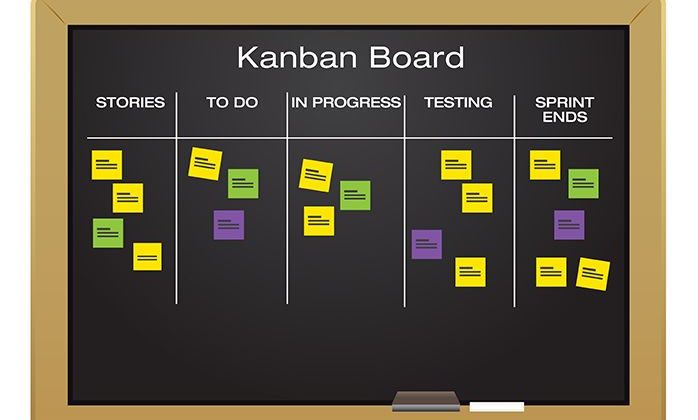

The 8 Pillars of TPM

The eight pillars of TPM are mostly focused on proactive and preventative techniques for improving equipment reliability.

| Pillar | What Is It? | How Does It Help? |

| Autonomous Maintenance | It gives operators the responsibility for basic maintenance tasks like cleaning, lubricating, and checking the machines. | It gives operators more control and responsibility over their machines, helping them understand the equipment better while keeping it clean, well-lubricated, and running smoothly. |

| Planned Maintenance | Schedules maintenance tasks based on predicted and/or measured failure rates. | It helps cut down on unexpected downtime by allowing most maintenance to be scheduled when machines aren’t in use. It also improves control over parts that wear out easily, which helps reduce excess inventory. |

| Quality Maintenance | Design error detection and prevention into production processes. Apply Root Cause Analysis to eliminate recurring sources of quality defects. | It focuses on improving quality by tackling the root causes of defects. By catching problems early, it reduces the number of defects and lowers costs, since relying on inspection alone is often costly and not always effective. |

| Focused Improvement | Have small groups of employees work together proactively to achieve regular, incremental improvements in equipment operation. | TPM encourages teams from different departments to work together to find and fix recurring problems. By bringing everyone’s skills together, it creates a strong system for continuous improvement. |

| Early Equipment Management | Directs practical knowledge and understanding of manufacturing equipment gained through TPM towards improving the design of new equipment. | New equipment gets up to speed faster because there are fewer problems at startup. Maintenance is easier and more reliable thanks to practical checks and employee input before the equipment is installed. |

| Training and Education | Fill in knowledge gaps necessary to achieve TPM goals. Applies to operators, maintenance personnel and managers. | Operators learn how to take care of their equipment daily and spot early signs of problems. Maintenance staff gain skills in proactive and preventive care, while managers are trained in TPM principles and how to coach and develop their teams. |

| Safety, Health, Environment | Maintain a safe and healthy working environment. | TPM helps remove health and safety hazards, making the workplace safer. Its goal is to create an accident-free environment for everyone. |

| TPM in Administration | Apply TPM techniques to administrative functions. | TPM goes beyond the factory floor by also reducing waste in office tasks. It helps improve support functions like order processing, purchasing, and scheduling to boost overall production. |

TPM & OEE: A Powerful Duo

OEE is the key metric used to measure TPM success. It calculates the percentage of planned production time that is truly productive.

OEE = Availability × Performance × Quality

OEE Benchmarks:

- 100% = Perfect production (theoretical maximum)

- 85% = World-class performance for discrete manufacturing

- 60% = Typical performance for discrete manufacturers

- 40% = Common for manufacturers without TPM programs

The Three OEE Components:

Availability measures downtime losses due to:

- Equipment breakdowns

- Setup and changeover time

- Material shortages

- Unplanned stops

Performance measures speed losses due to:

- Reduced operating speeds

- Minor stops and adjustments

- Equipment wear and aging

- Operator inefficiencies

Quality measures defect losses due to:

- Scrap and rework

- Process defects

- Startup losses

- Reduced quality standards

What’s Coming Next for TPM

TPM isn’t standing still. Here’s what I’m seeing more of these days:

- Going Green: Companies are finally caring about waste and environmental stuff, not just profits

- Smart Monitoring: Think of it like having a video game version of your machine that shows you what’s happening inside

- Better Predictions: Computers are getting scary good at knowing when something’s about to break

- Self-Fixing Machines: Some equipment can actually fix small problems by itself now

- Everything Connected: All your machines talking to each other and sharing information

Conclusion

Look, TPM isn’t rocket science. It’s about getting everyone to care about the equipment instead of just the maintenance guys. When that happens, things break less, quality goes up, and people get hurt less often. The thing is, it takes time and you’ve got to stick with it. Your boss needs to buy in, your workers need training, and you need patience. But once it clicks, the difference is huge.

Whether you’re just starting out or trying to make your current setup better, remember this – TPM works because people start taking pride in keeping things running right. In today’s crazy competitive world, that’s not just nice to have. It’s how you survive. The companies that figure this out will be the ones still around in ten years. The ones that don’t? Well, good luck to them.

Post Comment