Green Logistics: How Companies Can Go Sustainable in 2025

What is Green Logistics?

Green logistics is about moving products from one place to another while protecting the environment. It means finding ways to transport, store, and deliver goods that create less pollution and use fewer natural resources. Think of it as making the journey from factory to customer as eco-friendly as possible.

Traditional shipping and delivery methods often harm the environment through fuel emissions, excessive packaging, and wasteful practices. Green logistics offers a better path forward.

Why Should Companies Care?

Companies are discovering that going green isn’t just good for the planet – it’s good for business too. Here’s why:

Cost Savings: Using less fuel, reducing packaging, and improving efficiency often means spending less money. Many companies find that sustainable practices actually save them thousands of dollars each year.

Customer Demand: Today’s customers increasingly choose brands that care about the environment. A recent survey showed that 73% of consumers are willing to pay more for products from sustainable companies.

Legal Requirements: Governments around the world are creating new rules about emissions and waste. Companies that start going green now will be ready for these future requirements.

Better Reputation: Being known as an environmentally responsible company helps attract customers, employees, and business partners.

Simple Ways Companies Can Start Going Green

1. Choose Cleaner Transportation

Electric and Hybrid Vehicles: Replace gas-powered delivery trucks with electric or hybrid alternatives. While the upfront cost is higher, companies save money on fuel and maintenance over time.

Route Optimization: Use computer programs to find the shortest, most efficient delivery routes. This reduces fuel use and gets products to customers faster. Some companies have cut their delivery distances by 20% just by planning better routes.

Combine Shipments: Instead of sending multiple small deliveries, group orders together. One truck carrying ten packages uses much less fuel per package than ten separate trips.

2. Improve Packaging

Right-Size Packaging: Use boxes and containers that fit the product properly. Oversized packaging wastes materials and takes up unnecessary space in trucks.

Eco-Friendly Materials: Switch to recyclable, biodegradable, or reusable packaging materials. Cardboard, paper, and plant-based plastics are better alternatives to traditional plastic packaging.

Reduce Packaging Layers: Eliminate unnecessary wrapping, plastic inserts, and multiple boxes when one will do the job safely.

3. Make Warehouses More Efficient

Energy-Efficient Lighting: LED lights use 75% less energy than traditional bulbs and last much longer. This simple switch can significantly reduce electricity bills.

Smart Climate Control: Use sensors and automated systems to heat and cool warehouses only when needed. Some warehouses have reduced energy use by 30% with smart temperature control.

Solar Panels: Install solar panels on warehouse roofs to generate clean electricity. Many companies find that solar panels pay for themselves within five years through energy savings.

4. Work with Green Partners

Choose Sustainable Suppliers: Partner with suppliers who also prioritize environmental responsibility. This creates a green supply chain from start to finish.

Local Sourcing: Buy materials and products from nearby suppliers when possible. This reduces transportation distances and supports local businesses.

Green Shipping Companies: Work with delivery services that use clean vehicles and sustainable practices.

Real Examples of Success

IKEA: The furniture giant has committed to making all deliveries emission-free by 2025. They’re using electric vehicles in cities and have reduced packaging by 20% over five years.

Amazon: Despite its size, Amazon has pledged to be carbon neutral by 2040. They’re using electric delivery vans, renewable energy in warehouses, and AI to optimize delivery routes.

DHL: This shipping company has cut emissions by 29% since 2007 by using alternative fuels, efficient aircraft, and green buildings.

Getting Started: A Step-by-Step Approach

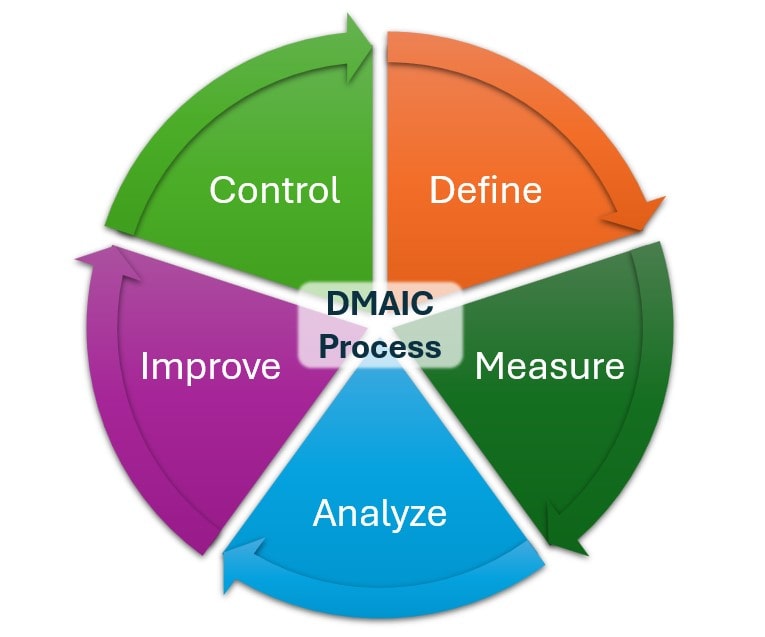

Step 1: Measure Current Impact

Before making changes, companies need to understand their current environmental footprint. Track fuel usage, packaging waste, energy consumption, and transportation distances.

Step 2: Set Realistic Goals

Start with achievable targets like “reduce packaging waste by 15% in one year” or “cut fuel consumption by 10% in six months.” Small wins build momentum for bigger changes.

Step 3: Pick Easy Wins First

Begin with changes that are simple and cost-effective. Route optimization software, LED lighting, and packaging improvements often provide quick results.

Step 4: Invest in Bigger Changes

Once initial improvements are working, invest in larger initiatives like electric vehicles, solar panels, or warehouse automation.

Step 5: Track Progress

Regularly monitor results and adjust strategies. Celebrate successes and learn from setbacks.

Overcoming Common Challenges

“It’s Too Expensive”: While some green technologies have higher upfront costs, most save money over time through reduced fuel, energy, and material expenses. Many companies also find government incentives and tax breaks that help offset initial investments.

“Our Customers Won’t Pay More”: Studies show that most customers will pay slightly more for sustainable products and services. More importantly, efficiency improvements often reduce costs, allowing companies to maintain competitive prices.

“It’s Too Complicated”: Start small and build gradually. Even simple changes like better route planning or LED lighting make a real difference.

The Future of Green Logistics

The logistics industry is rapidly evolving toward sustainability. Emerging technologies like drone deliveries, autonomous electric vehicles, and AI-powered optimization systems will make green logistics even more effective and affordable.

Companies that start their sustainability journey now will be ahead of the curve when these technologies become mainstream. They’ll also be ready for increasingly strict environmental regulations and growing customer expectations.

Conclusion

Green logistics isn’t just a trend – it’s the future of business. Companies that embrace sustainable practices today will enjoy cost savings, customer loyalty, and competitive advantages tomorrow.

The key is to start somewhere. Whether it’s optimizing delivery routes, switching to LED lights, or reducing packaging waste, every step toward sustainability makes a difference. As these small changes add up, companies often discover that being environmentally responsible is also the smart business choice.

The journey toward green logistics may seem challenging, but with simple steps and steady progress, any company can make a positive impact on both their bottom line and the planet.

Post Comment