What Is Supply Chain Management ? A Simple Guide for Beginners

You know that feeling when you walk into a store and everything you need is just… there? Your favorite snacks, the exact phone charger you broke last week, even that weird specialty ingredient for the recipe you found on TikTok. It feels like magic, but it’s actually something way cooler – it’s supply chain management in action.

I used to think supply chains were just boring business stuff until I really started paying attention to how things actually get to us. Now I’m kind of obsessed with it, and I think you will be too once you see what’s really happening behind the scenes.

What Even Is a Supply Chain?

Okay, so imagine you’re making a sandwich. Simple, right? But think about it – the bread came from a bakery that got flour from a mill that got wheat from a farm. The cheese came from a dairy that got milk from cows that ate grass that grew in fields. The turkey came from… well, you get the idea.

Every single thing in that sandwich has its own story, its own journey. Multiply that by literally everything you own, use, or consume, and you start to get a picture of how complex this whole system really is.

A supply chain is basically the entire network of people, companies, and processes that get stuff from “raw materials” to “in your hands.” It’s not just one line – it’s more like a web with thousands of connections.

So What’s Supply Chain Management Then?

Supply Chain Management (SCM) is like being the conductor of the world’s most complicated orchestra. Instead of musicians, you’re coordinating farmers, factory workers, truck drivers, warehouse staff, and store employees. Instead of making music, you’re making sure people get what they need, when they need it, without paying crazy prices.

The people who do this job are basically wizards. They have to predict the future (how much stuff will people want?), solve problems in real-time (a hurricane just hit a major port!), and somehow keep costs reasonable while making sure quality doesn’t suffer.

Let Me Tell You About Your Morning Coffee

I’m a coffee person – like, seriously addicted – so let me walk you through what happened before that first sip hit your lips this morning.

It Started on a Farm Somewhere, probably in a mountainous region of Colombia or Ethiopia, a farmer was dealing with unpredictable weather, fluctuating prices, and the constant challenge of timing the harvest just right. Too early and the beans aren’t developed. Too late and you miss the market window.

Then Came the Traders Coffee doesn’t go straight from farm to your cup. Traders buy from multiple farms, test the quality, and figure out how to ship tons of beans across oceans without them going bad. They’re dealing with currency exchange rates, shipping schedules, and quality standards from different countries.

The Ocean Journey Your coffee beans spent weeks on a cargo ship, probably stacked with containers from dozens of other products. Supply chain managers were tracking that ship, watching weather patterns, and coordinating with ports to make sure everything moved smoothly.

The Roasting Game At a roasting facility, someone had to predict how much coffee you and millions of other people would drink, then time the roasting perfectly. Coffee goes stale pretty quickly, so they can’t make too much too early, but they also can’t run out.

Getting to Your Store Finally, distribution networks figured out exactly how many bags each store in your area would need, loaded up trucks, and delivered everything on schedule. The store’s computer system probably automatically reordered more coffee before they even ran out.

And that’s just coffee! Imagine orchestrating this for literally every product in existence.

Why This Actually Matters to You

Good supply chain management is the difference between a world that works and one that doesn’t. Here’s what I mean:

When It Works Well: You can get almost anything you want, pretty quickly, at a reasonable price. Amazon Prime, same-day grocery delivery, walking into Target and finding exactly what you need – that’s all SCM excellence.

When It Breaks Down: Remember the toilet paper situation in 2020? Or trying to buy a car during the chip shortage? That’s what happens when supply chains get disrupted.

Companies that nail supply chain management can do amazing things. Zara can go from design idea to clothes in stores in just a few weeks. Apple can launch a new iPhone globally on the same day. Your local grocery store somehow keeps fresh produce available year-round.

The Tech Revolution Is Changing Everything

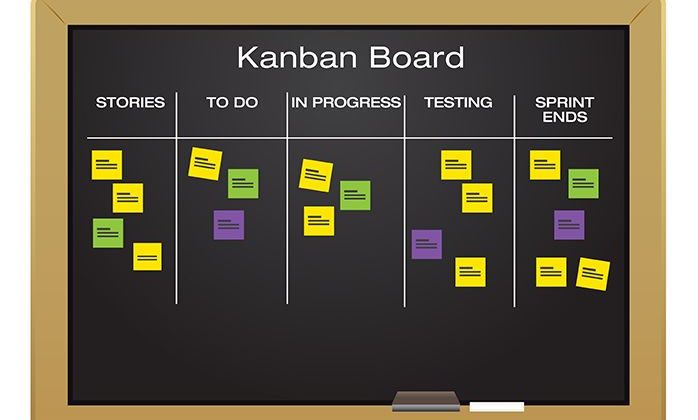

The coolest part about modern supply chains is how high-tech they’ve become. We’re talking about:

AI That Predicts the Future: Algorithms that can predict what you’ll want to buy before you even know you want it. That’s how Amazon can have stuff at a warehouse near you before you order it.

Real-Time Tracking: You can watch your DoorDash driver in real-time using the same technology that tracks billion-dollar shipments across the globe.

Robots Everywhere: Amazon warehouses have thousands of robots moving products around. It’s like a real-life version of those factory videos you see on social media.

Virtual Reality Planning: Companies create digital copies of their entire supply chains to test different scenarios without screwing up the real thing.

Even Small Businesses Are Playing This Game

You might think supply chain management is only for huge corporations, but that’s not true at all.

My friend runs a small online jewelry business from her apartment. She has to coordinate with suppliers in Thailand for materials, manage inventory so she doesn’t run out of popular items, work with shipping companies to get orders delivered on time, and handle customer service when things go wrong. That’s supply chain management on a smaller scale.

The local restaurant you love? They’re managing supply chains for dozens of ingredients, trying to predict how busy they’ll be each day, and coordinating with multiple suppliers to keep costs down while maintaining quality.

When Things Go Wrong, We All Feel It

The past few years have been like a masterclass in supply chain problems:

The Toilet Paper Thing: Panic buying showed how supply chains optimized for normal demand can’t handle sudden spikes. The paper existed – the problem was getting it packaged and distributed fast enough.

Computer Chips: A shortage of tiny semiconductors affected everything from cars to gaming consoles. It turns out almost everything electronic needs these specialized components, and they take months to produce.

The Suez Canal: When that giant ship got stuck and blocked the canal, it messed up global shipping for months. One boat, thousands of delayed products.

These big disruptions basically taught companies a hard lesson: yeah, going with the absolute cheapest supplier might save money upfront, but if that’s your only supplier and something goes wrong, you’re screwed. It’s like only having one friend – if they’re busy, you’re stuck at home alone on Friday night.

What’s Next for Supply Chains?

Honestly, some of the stuff happening in supply chain management right now is pretty wild:

The Green Revolution: Companies are finally starting to give a damn about the environment. I mean, it’s about time, right? This means they’re trying to ship stuff shorter distances, use clean energy in their warehouses, and stop using packaging that takes 500 years to decompose. My cousin works at a company that switched to biodegradable packaging last year – it costs more, but customers actually care about this stuff now.

Bringing Production Home: Remember when everything was “Made in China”? Well, that’s changing. With 3D printing and other cool tech, companies can make some products right where people live. It’s faster, creates local jobs, and honestly, it just makes more sense for a lot of things.

Robots Taking Over: Okay, not in a scary Terminator way, but self-driving trucks are already being tested, delivery drones are becoming normal in some places, and warehouses are getting so automated it’s like something out of a sci-fi movie. I saw a video of an Amazon warehouse recently – it’s basically robots playing the world’s most efficient game of Tetris.

Know Where Your Stuff Comes From: More people want to know the story behind their purchases. Was this made by someone getting paid fairly? Is this company destroying rainforests? There are apps now that can tell you the entire journey of your product just by scanning a barcode. It’s pretty cool if you’re into that kind of thing.

Here’s the Thing

Supply chain management is one of those invisible things that runs our entire world. You probably never think about it – until your Amazon delivery is late or your favorite restaurant runs out of your go-to dish.

It’s wild when you realize that the reason you can order literally anything at 2 AM and have it show up at your door is because thousands of people are coordinating this massive, global dance 24/7. It’s why you can get strawberries in December and why that random thing you needed for a project is somehow sitting on a shelf at your local store.

Once you start paying attention to it, you can’t unsee it. Every single thing around you right now – your phone, your clothes, that random pen on your desk – has this incredible story of how it got to you. And honestly? Most of those stories are way more interesting and complicated than you’d think.

We live in this crazy connected world, and supply chain management is basically the invisible glue holding it all together. Kind of amazing when you stop and think about it.

3 comments